How Will Hot Forging Be In The Future.

3 mm (0. 012 in), surfaces are tidy, as well as draft angles are 0. 5 to 1. Device life is almost dual that of conventional building because call times get on the order of 0. 06-second. The downside is that this procedure is only practical on smaller symmetrical components and cost; the preliminary financial investment can be over $10 million, so large amounts are needed to validate this process.

It is then descaled with rollers, sheared into spaces, as well as transferred via a number of successive forming phases, throughout which it is dismayed, preformed, final created, and punctured (if required). This process can likewise be paired with high-speed cold-forming procedures. Generally, the cool creating procedure will certainly do the finishing stage to ensure that the advantages of cold-working can be acquired, while maintaining the high speed of automatic warm forging.

Manual transmission gears are an instance of automatic hot building utilized in combination with cool working. Roll building [modify] Roll creating is a procedure where round or flat bar supply is decreased in thickness and also increased in size (Hot Forging). Roll forging is carried out making use of 2 round or semi-cylindrical rolls, each consisting of several shaped grooves.

The piece is after that moved to the following collection of grooves or turned about and also reinserted right into the exact same grooves. This continues until the wanted form and also dimension is achieved. Hot Forging. The benefit of this procedure is there is no flash and also it passes on a desirable grain framework right into the work surface.

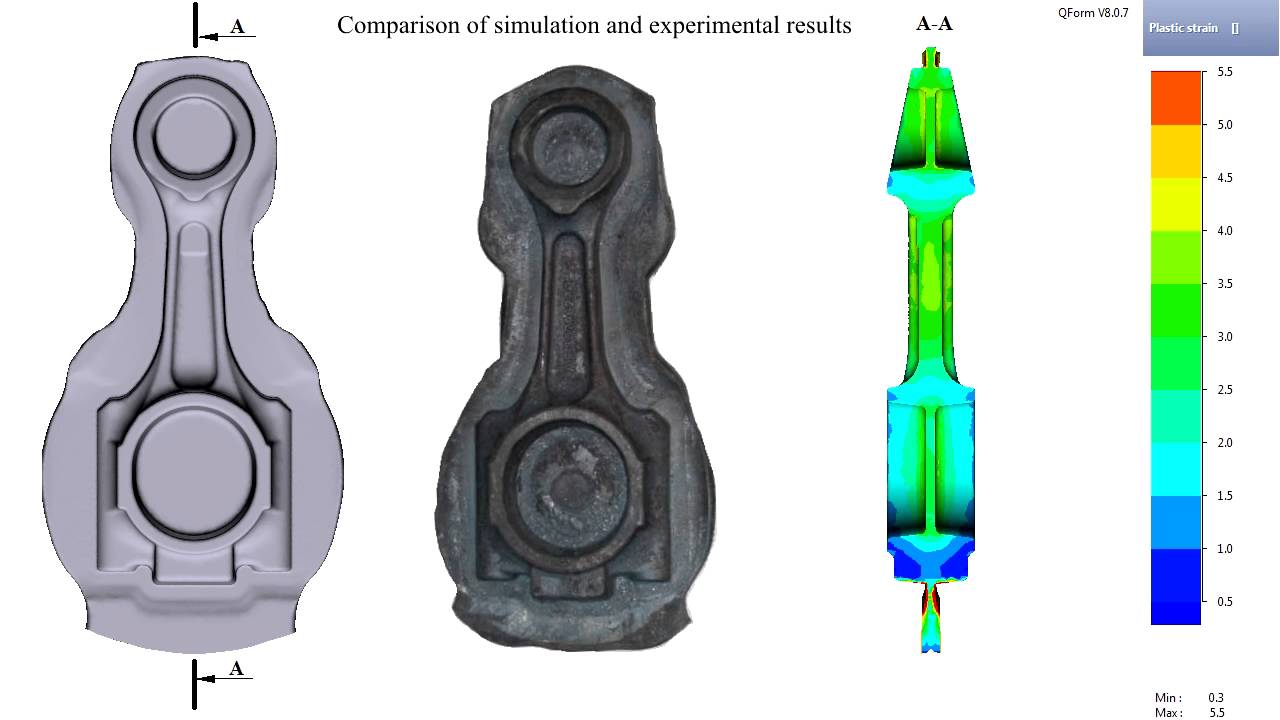

Net-shape as well as near-net-shape forging [modify] This procedure is additionally recognized as accuracy forging. It was created to minimize expense as well as waste related to post-forging operations. Therefore, the end product from a precision building requirements little or no final machining. Price cost savings are acquired from using less material, as well as hence less scrap, the total reduction in power made use of, and the reduction or elimination of machining.

The downside of this procedure is its price, as a result it is just applied if considerable cost reduction can be achieved. Cold forging [modify] Near internet form forging is most usual when components are created without warming the slug, bar or billet. Light weight aluminum is a typical material that can be chilly created depending on final form.

Induction forging [edit] Unlike the above processes, induction forging is based upon the kind of home heating design used. Several of the above procedures can be made use of in conjunction with this home heating method. Multidirectional creating [edit] Multidirectional Forging is creating of a work piece in a solitary action in numerous directions. The multidirectional developing occurs through useful measures of the tool (Hot Forging).

Isothermal forging [modify] Isothermal building is a process whereby the materials and also the die are warmed to the same temperature (significance "equal"). Adiabatic home heating is utilized to help in the contortion of the material, implying the stress rates are highly managed. Frequently utilized for creating aluminium, which has a lower creating temperature than steels.

Brass, bronze, copper, precious steels as well as their alloys are manufactured by cold creating procedures, while each steel requires a various building temperature. Forging of aluminium [edit] Aluminium creating is done at a temperature variety in between 350550 C Forging temperatures over 550 C are as well near the solidus temperature of the alloys and lead along with varying reliable strains to unfavorable work surface surfaces and also possibly to a partial melting along with fold formation.

评论

发表评论